A summary of the LCDM Phase 2 project you find on this link https://seiia.se/industrial-interoperability-summit-2021/

Why work together? We believe that cooperation and openness strengthen the competitiveness of Swedish industry and add value to all involved. We believe that much of the work currently done by each plant owner and their suppliers in specifying and handling information exchange in projects can be simplified and standardized to a common standard. By using common templates, structures and designations, we can jointly share the administrative, development and adaptation costs that need to be done by all parties involved. We believe that the role of document control needs to be changed to information control and data quality and to make that change we can implement better and more efficiently together in the industry compared to all of us working in our own chambers.

What do we want to do? LCDM phase 2 looks specifically at how we can use standardized concepts. How mature are we today if we compare ourselves to the rest of Europe and their working methods in projects where they work with the same standard? How much can be used by what is already done by simply mapping it to a standard? How much customization does a plant owner’s document control need to do to arrive at information and data quality management? Can we quantify the benefits of a joint collaboration in terms of time, money and quality?

LCDM Phase 2 is a continuation project Below part of the project application for LCDM phase 2 is enclosed. SEIIA has with the support of PiiA and Vinnova runing the continuation project for LCDM. Processindustry owners who, in pilot form test the concepts that SEIIA will work with. Running the CFIHOS and DEXPI concept/standards sharply on a smaller plant part to demonstrate an improved information transfer at completion. EPC and consultants who want to start working according to the new concepts that the standardization provides. Suppliers of everything from ready-made Turn Key plants to equipment suppliers

LCDM phase 2 project idea Already in the application for phase 1 of the LCDM project, a need was expected for a phase 2 that would become more concrete in pilots after phase 1 had created the necessary conditions in the form of understanding, knowledge, contacts and relationships and plans for the continuation. The result of phase 1 was a little more than the project expected, but all before phase 2 it is worth noting.

ü It takes time to build relationships, understanding and industry participation.

ü Do not lose the pace, dedication and thus confidence in SEIIA’s ability to deliver

ü Financial (public) support is needed for a limited continued build-up period.

The phase 1 survey shows that the industry, where the plant owners dominated, wants to participate and work on the conditions is clear and the right ones. What they are is described from phase 1 and something that the phase 2 project work with. Important to note as central to the idea of the project is not to develop new but to build on international results, development and apply this by continuing to build relationships with key Nordic and European partners via SEIIA and its members and participate in their work. I In Sweden SIS and TK280 responsible for ISO 15926 didn’t have any operational work around the standard and SEIIA takes the role that is missing today, and we also profile ourselves internationally within the standardization in this area. It is also important in phase 2 to continue to develop industrial collaborations, both started and new, to find synergies with other relevant ongoing projects, to strengthen the international perspective and to cover the entire industrial chain, which includes both process and discrete manufacturing industries. Objectives of the project The project has five main goals where results are to be delivered

ü Skills development of participating project partners in the project areas

ü 4 pilots /test beds where real projects in the industry test the CFIHOS / DEXPI concepts.

ü Support companies with knowledge and activities in theadaptation and further development of their services and products

ü Sign cooperation agreements. MoU with internationalnon-profit organizations already working with Interoperability.

ü Hold an ”Industrial Interoperability Summit”2021

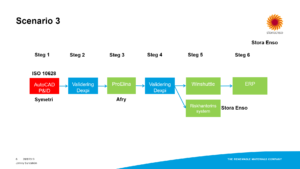

Project budget We have project budget on SEK 3.2 million and the support from PiiA and Vinnova are in budget SEK 1,2 million. Progress and pilots During 2020 the Corona pandemic have affected the project with less or since March no physical meetings. But we think we have succeeded in our efforts to deliver results that will help Swedish industry to get better quality and more value into the information handover. Most because we could minimize the manual work to send and receive information required in the handover of projects to operations. Pilot 1 Stora Enso Setting up AutoCAD P&ID for flowchart drawing based on established standards and the open standard DEXPI, which is a concept with data exchange specifications in the neutral format XML. The project is in the last phase were will verify the result of the engineering done in AutoCAD P&ID/ DEXPI compatible version. The validation is done in Prolina by AFRY.

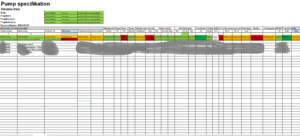

Pilot 2 SCA Östrand Pulpmill and Pilot 3 Vakin Both pilots have almost the same agenda and are parallel the uses of CFIHOS concept. Both have initially an Excel sheet with requirement of information from there contractors and vendors. But they are unique design and could not be automatic handled by the contractors and vendors. In the project we have worked with getting better knowledge about CFIHOS and then work with a CFIHOS specified Excel sheet that have identifiers based on CFIHOS ID not own unique ID. That’s opportunity with the CFIHOS ID it is regardless of who is the sender or recipient the same definitions could be used and both sides could make automatic read and write applications to their systems. API.

An example on a generic pump specification

Pilot 4 Holmen Paper / Iggesund Boardmill Holmen has a project where SiteBase and Aveva Everything3D will be integrated and they are trying to base this integration on ISO 15926 instead of a traditionally Point To Point solution.